Aluminium Panel Fixtures

Digitising the body of rare and interesting cars is very useful. The data can be digitally archived for use should the car be involved in any kind of incident at a future date. This can be invaluable as once a car has been damaged it may be difficult or impossible to find accurate data and measurements needed in restoration. We have scanned cars and held the data for over five years before being called upon to manufacture a body fixture. This type of insurance against the loss of the original body work parameters is highly valued where there is risk of damage to the car such as in the world of racing.

The process of creating a fixture for panels is:

- Laser scan – the exterior of the car is laser scanned, this generates an accurate point cloud that replicates the geometry of every feature of the car body

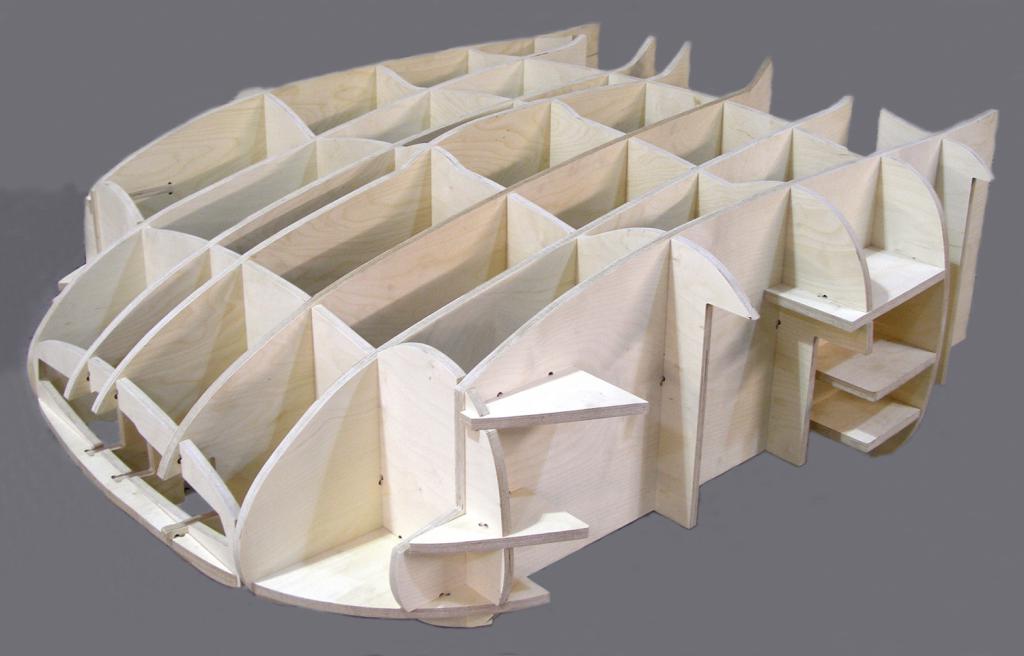

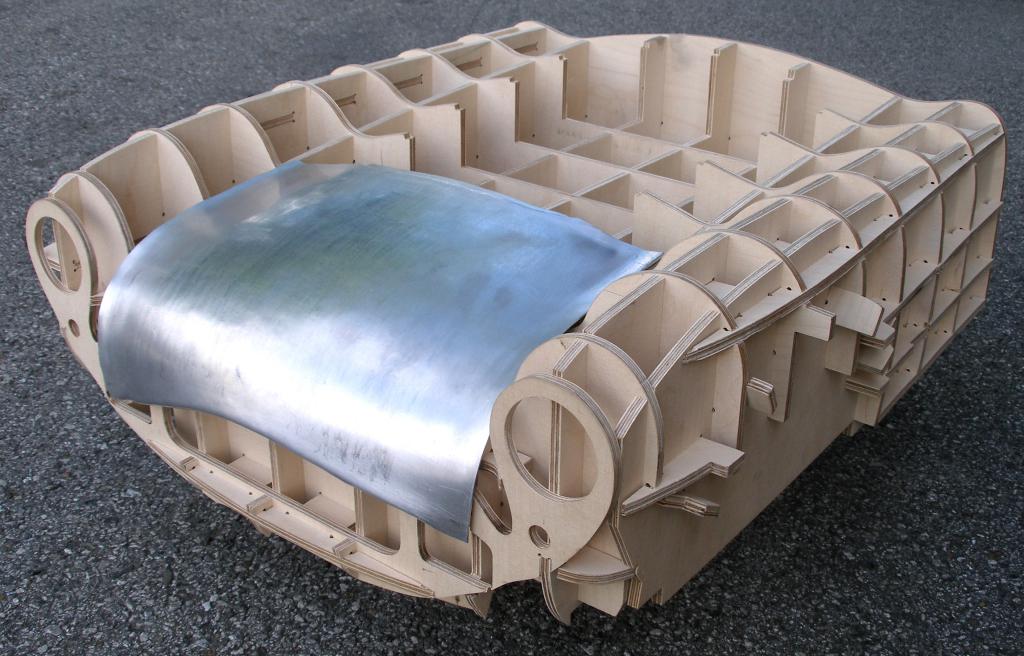

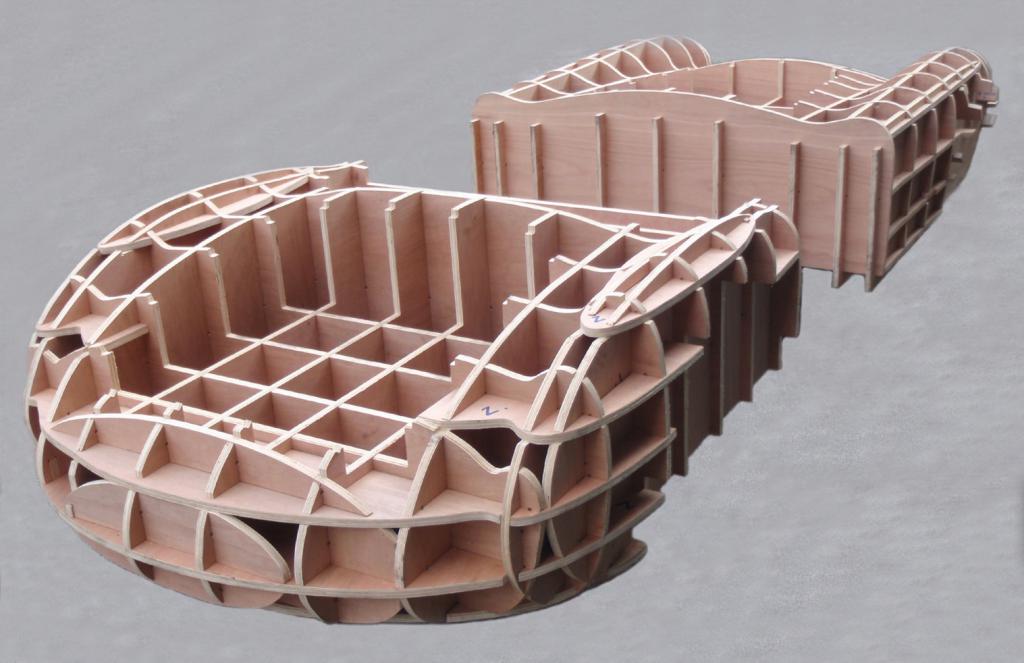

- Fixture design – a series of sections are created through the scan data to produce the ‘egg crate’ buck. We normally meet with the body panel manufacturer to decide how many and where the sections are required

- Fixture manufacture – the section drawings are emailed to a CNC wood cutting company and they are routed from plywood. These sections are assembled to create the buck

- Panel manufacture – the panels are accurately formed to fit the fixture

Examples of parts we have made include:

-

Zagato TZ1

-

Tecmec tail

-

Lister Knobbly

-

Lister Bristol

-

HWM

back to homepage

|

07979 603111 |

|---|---|

|

info@a2p2.co.uk |