3D Laser Scanning

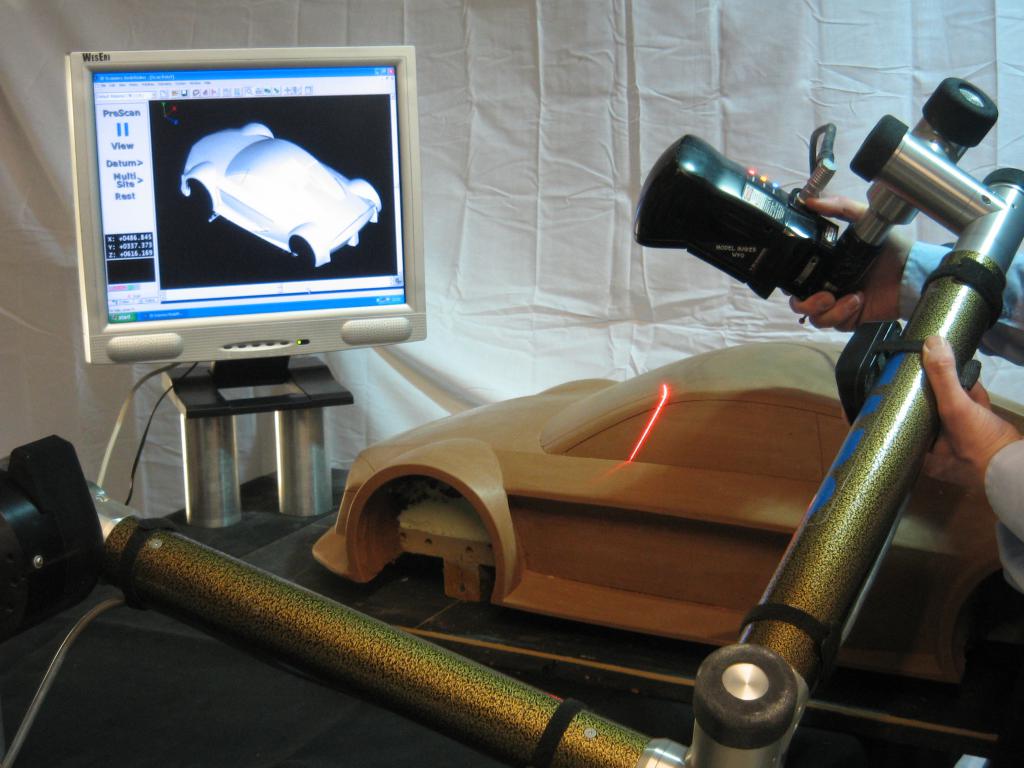

A 3D laser scanner is used to capture precise measurements of the physical characteristics of the part or object being scanned. Using a practiced hand following years of experience in this technique our team will carefully and precisely sweep the scanner beam across all surfaces of the object and record exact data to create a computerised 3D model of the item, consisting of thousand of tiny points of reference.

The point cloud is the raw scan data which is then transferred into a Computer Aided Design (CAD) software program in order for it to be translated into meaningful data which can be manipulated by our designers.

Scanning an object provides an accurate computer model of the actual part in cases where the part was:

- Built prior to computer aided design

- Original data is not available

- The part is handmade and original data may not be absolutely correct following potential modifications in the production process.

- Data requires manipulation such as upscaling or downscaling.

An example of this is in classic cars that are raced. Owners often have their car scanned in order to produce an accurate body fixture on which to form panels should the car sustain damage in a race.

It is even possible to scan the exterior of a model car and manipulate the data to provide a blueprint for a full size car body.

It is even possible to scan the exterior of a model car and manipulate the data to provide a blueprint for a full size car body.

Component parts (e.g. a suspension wishbone) that are broken may no longer be produced so are often not readily available when it comes to sourcing replacements. By scanning the broken part the data can then be manipulated to “fix” the break so that a working part can be manufactured.

Enhancing performance can also be done in a simulated rather than physical environment. In order to do this in CAD the working part (from a simple cantilever to a full engine) must first be scanned.

|

07979 603111 |

|---|---|

|

info@a2p2.co.uk |