Sand Casting

There are several steps to making a sand cast component.

- Laser scan – the component is scanned, this gives a 3D point cloud that accurately represents the size and shape of the part

- Casting CAD model – CAD geometry is drawn incorporating machining allowance and casting contraction/shrinkage

- Finished machined CAD model – another CAD model is created to represent the finished machined part this incorporates all machining, drilling, tapping and boring features.

- Engineering drawing – from the cad model engineering drawings are produced to give to the machine shop to machine the casting.

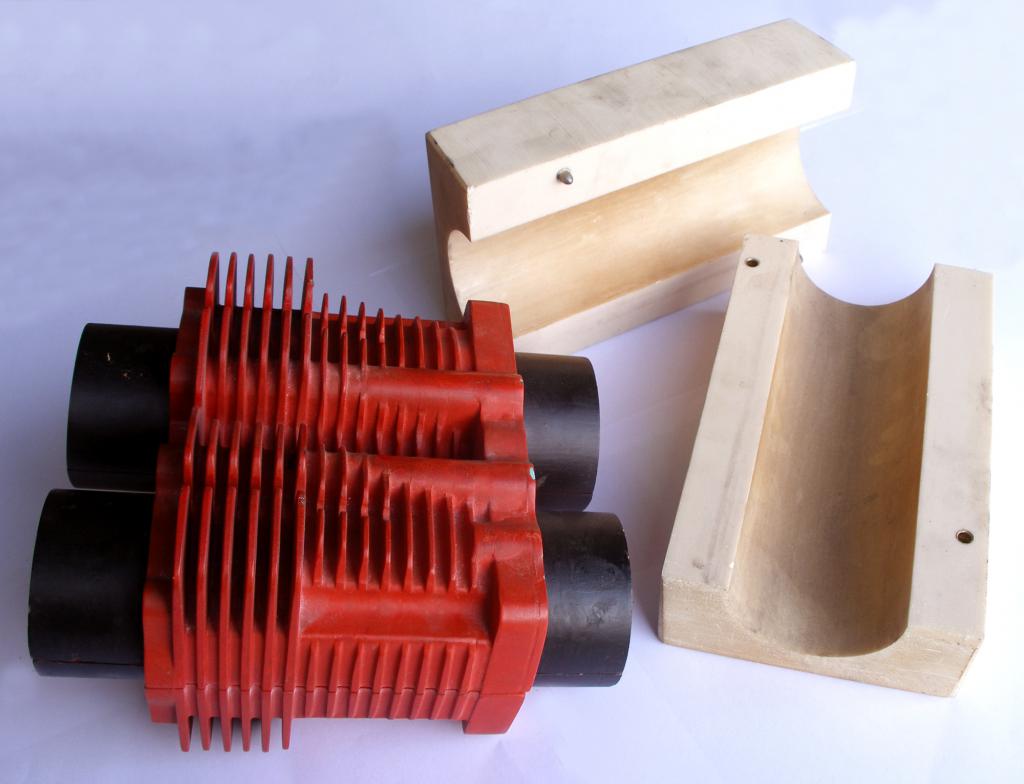

- Pattern design – casting patterns are designed from the casting model and then machined from a polyurethane resin / ureol.

- Castings – the patterns are used by the foundry to produce castings.

- Machining – the castings are then machined to produce the finished component

We can supply a finished product at any stage of the process above.

-

If you are a CAD designer - we can supply the scan data

-

If you are a pattern maker – we can supply the CAD model

-

If you are a machine shop – we can supply the machining drawings

-

If you are a foundry – we can supply the patterns

-

If you just want a finished part – we can do the whole job!

Examples of sand cast parts we have made include, magnesium gearbox casings, cast iron brake discs, aluminium cylinder heads, water pumps, oil pumps, rocker covers, sumps, crankcases and engine blocks.

|

07979 603111 |

|---|---|

|

info@a2p2.co.uk |